The Endless Possibilities of Using IoT for Industrial & Commercial Electrical Ecosystem’s Predictive Maintenance.

December 27, 2021EVIO good practices for Cable Laying process

February 17, 2022

Good Practices : Earthing & cable end termination

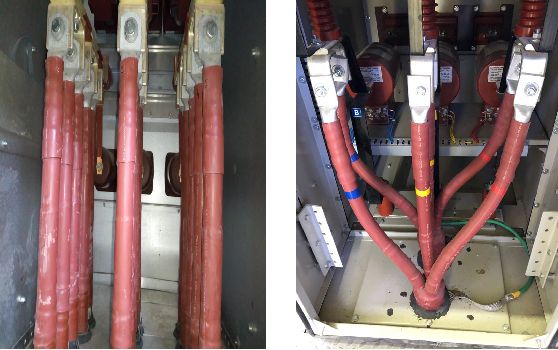

Cable End termination- Method Statement for Glanding & Termination.

- Make holes in gland plates for all likely caster initially itself. Holes to be made by drilling of proper size. No gas cutting shall be done for hole making.

- The glanding shall be done with suitable arrangement for earthing the gland. Glands shall be earthed so that positive earthing is achieved.

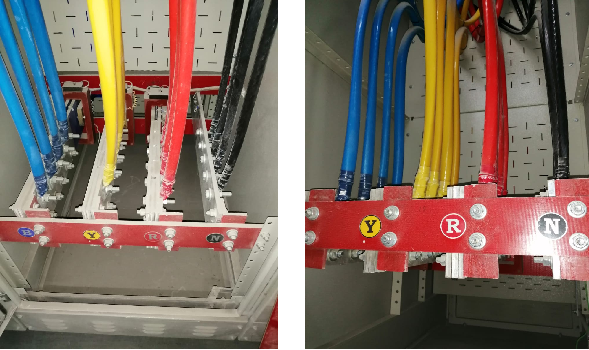

- The ferrules shall be used for multicore cable connections. And the lugs used shall be tinned copper for copper and for Aluminum for Aluminum accordingly.

- Ensure that the connectors are of the correct size for the conductor concerned and as recommended by Manufacturer.

- Ensure that the palm of the connector shall be of such shape and size that standard wrenches relevant to IS applicable to the size of stud for which the connector is designed shall like flat on both faces of the connection palm where the holes in the wrenches and the palm are co-incident.

- Ensure that the Dowells inhabitant paste is applied between the conductor and lug, before compression.

- Insulate the lug neck, crimped on the conductor, with proper tape insulation sleeve.

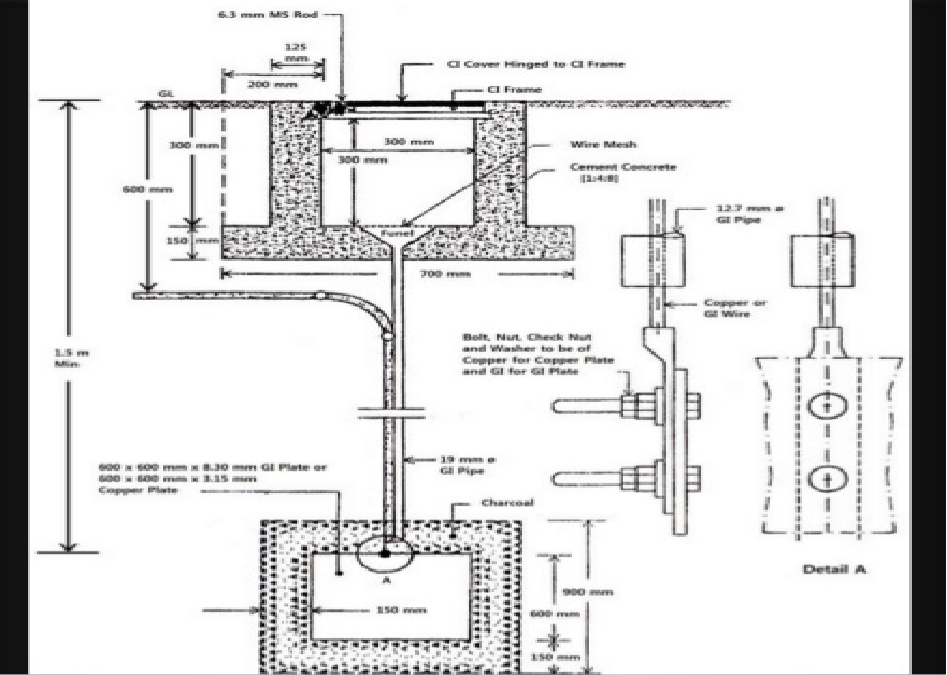

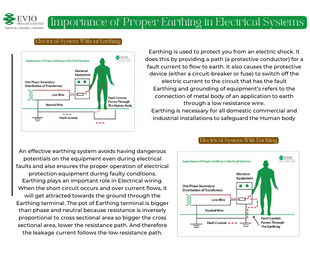

Earthing system.

- All electrical equipment’s must be efficiently, double earthed in accordance with the requirement of IS 3043 and relevant regulations of Electric Supply Authority.

- The earth pits shall be as per I.S. Standard, with proper arrangement for testing.

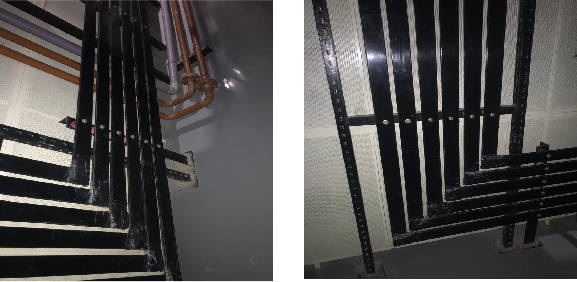

- All earthing conductors shall be hot dip galvanized/electrolytic grade bare copper conductor. The main earthing rings shall be done as per practice laid in Indian Standard, and all hardware for bolted joints shall be galvanized & Tinned copper lugs .

- The earthing of individual electrical equipment shall be done by two distinct strips / conductors as per practice laid in Indian Standard.

- All electrical equipment shall be connected, to the earth bus, at two points, except the lighting fittings and junction boxes.

- Earthing resistances shall be measured and recorded periodically. The effective earth resistance of the system shall be less than ‘one Ohm’.

- Removable test links shall be provided near the earth pits to facilitate testing of earth pits.

- where the earthing terminal diameter provided on equipment is larger than quarter of the size of the earth conductor, connection shall be made using a wider flag welded to the conductor.

Installation of Earth conductor